Silicon (Hardener)

This is the brand of silicon I will be using for molding

Silicon Part A

Both Part A & B combine in a 1:1 ratio

Material Safety Data Sheet

.

Resin

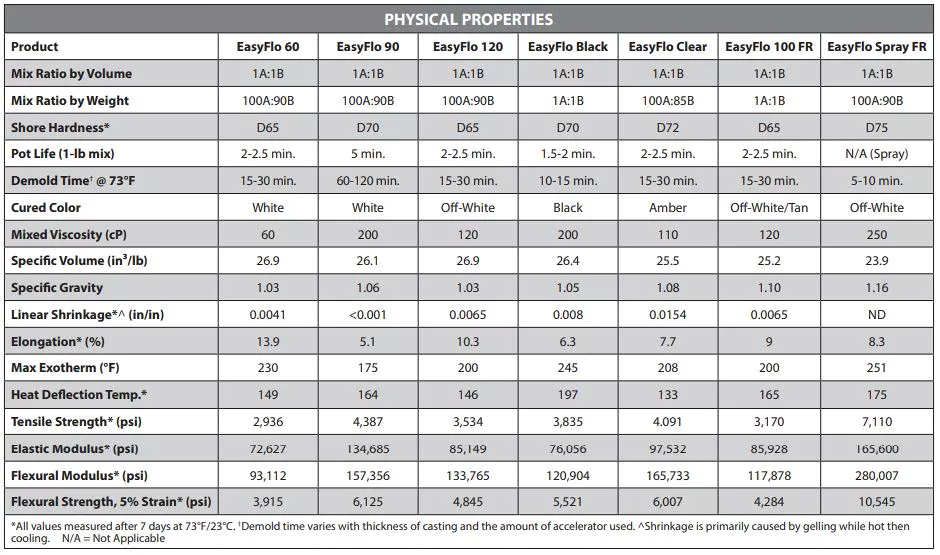

These are the specifications of the various epoxy resins

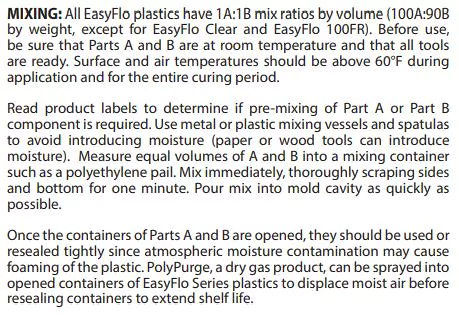

Instructions

These are the mixing and handling instructions

Safety Precautions

Here, safety precautions for handling the epoxy resin can

be found

Silicon Pouring

The silicone is poured into the corner so that htere would

not be any trapped air bubbles on the surface of the model

Silicon Curing

The datasheet has indicated 24hs for a full cure

Cured Silicon Mold

The silicone mold has set after 24 hours

Demolding

The foam is broken off and peeled away

Low-poly Heart (Mold)

The mold turned out good

Resin Casting Preparation

.

Materials

I used alcohol Ink, blue and red foils, mica powder and

resin

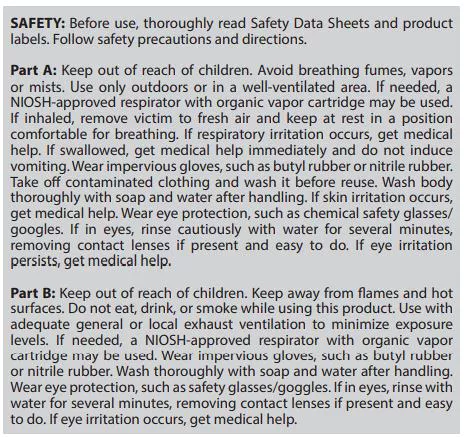

Precision Scale

I used a very precise scale (+0.01) to measure a ratio of

3:1 resin and hardener

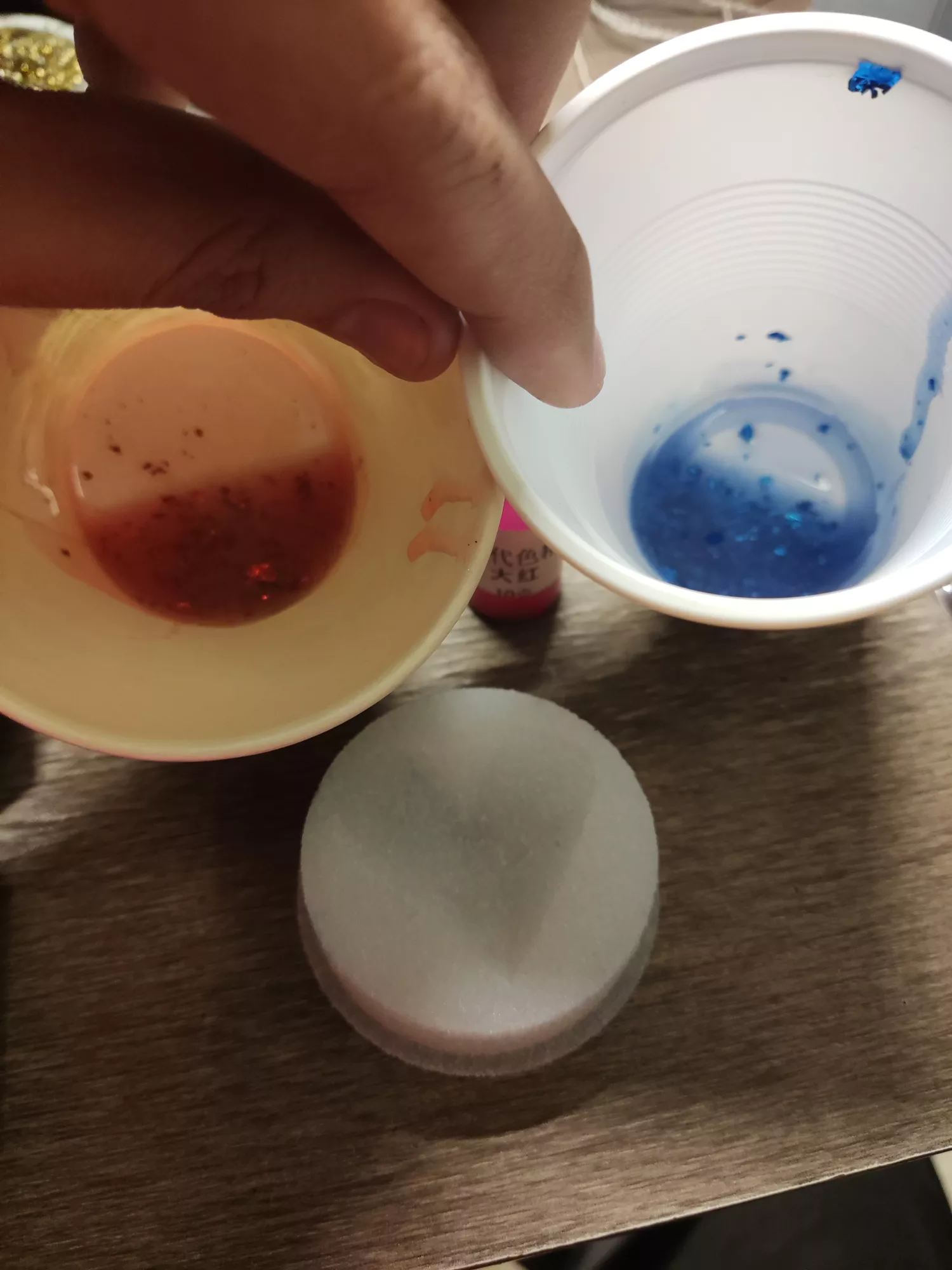

Red-tinted resin

I've added a drop of red alcohol ink, some red foils and

white mica powder

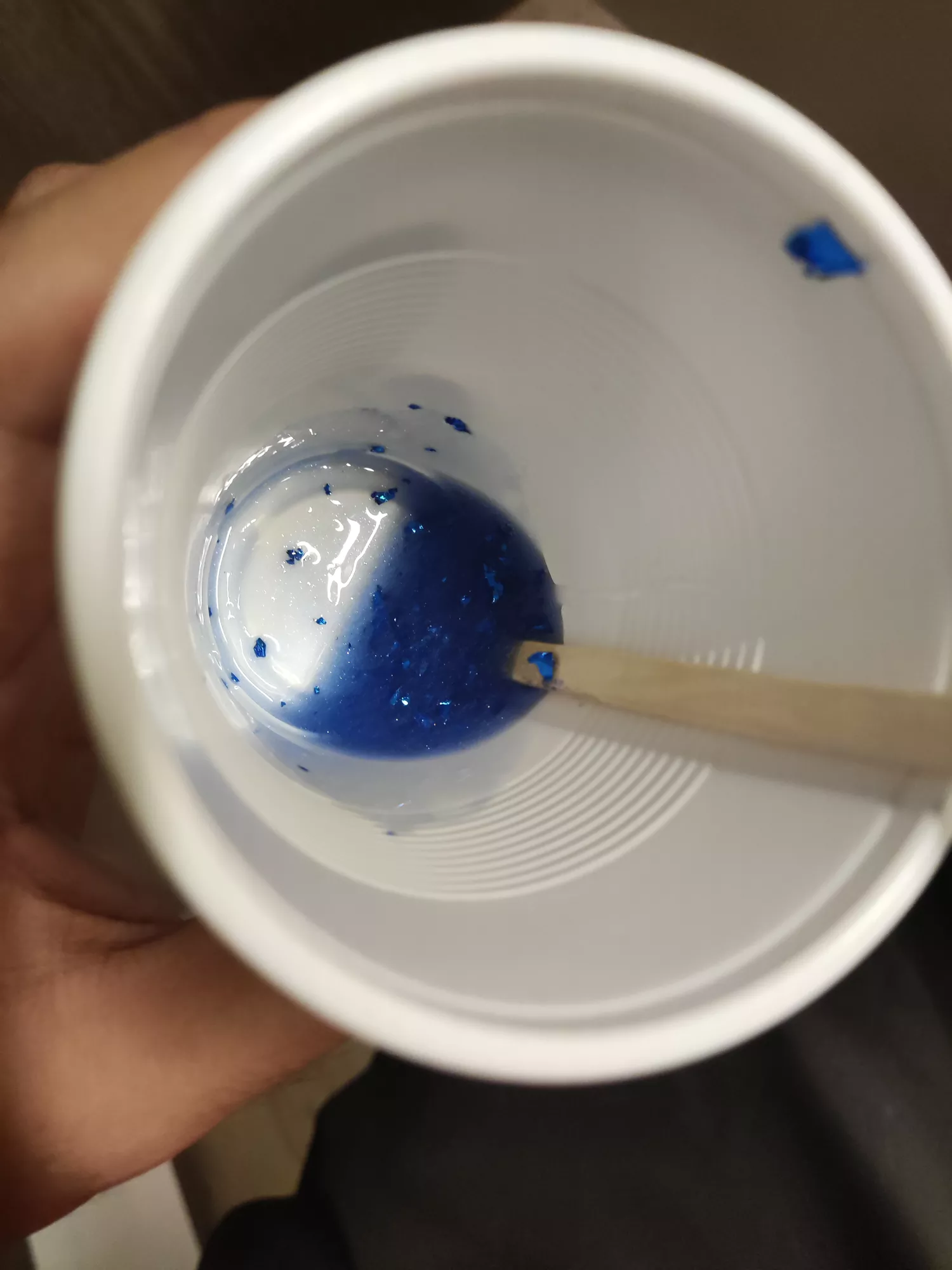

Blue-tinted resin

I've added a drop of blue and black alcohol ink, some blue

foils and blue mica powder

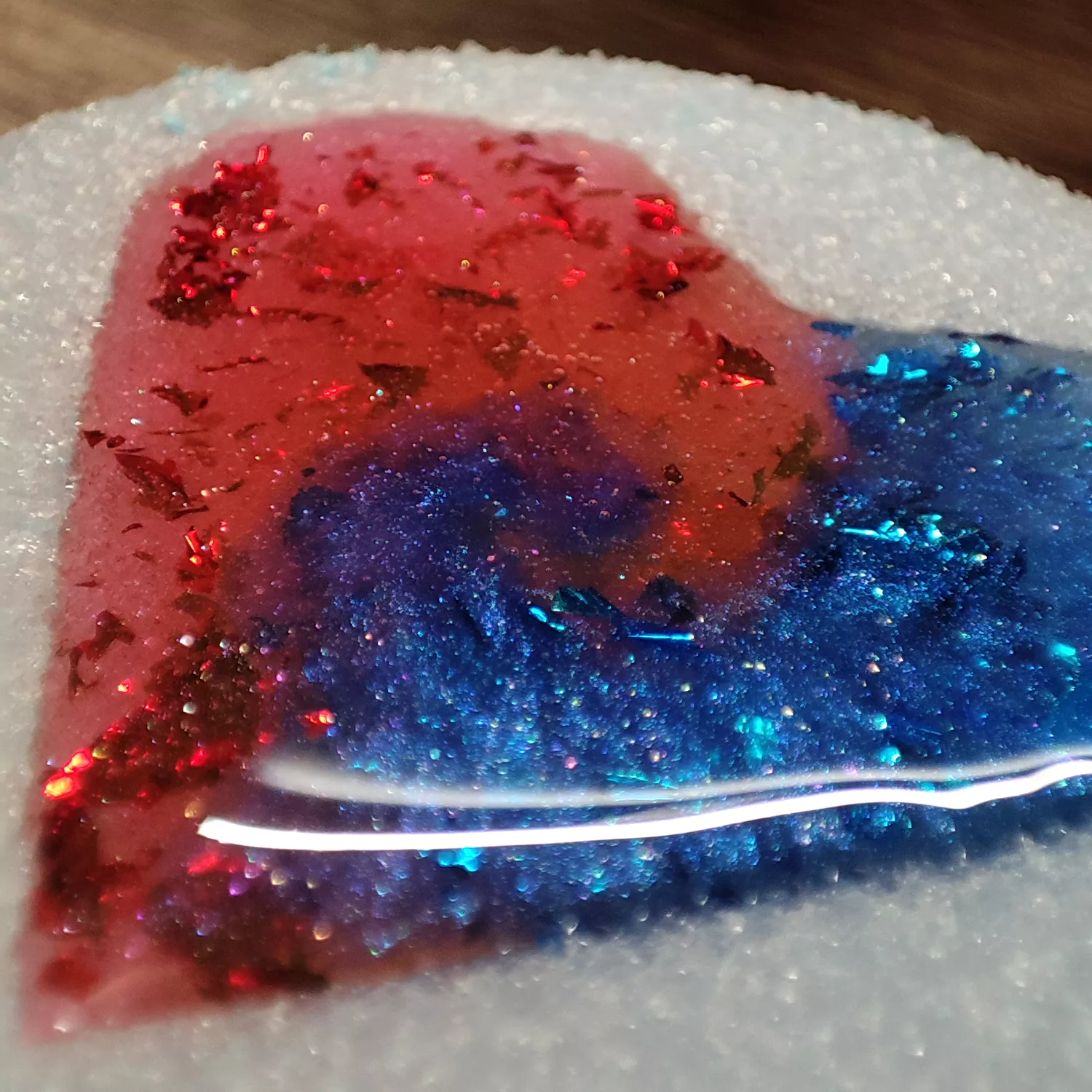

Segregated Pour

I intend to create a distinct contrast of color by pouring

the resins at extreme ends of the mold

Resin Curing

The design turned out decent

Close-Up Picture

🌌

Guitar Pick Mold

I have some leftover resin and decided to make some guitar

picks with it

Patience....

Looks Good 🌌

Result

looks good