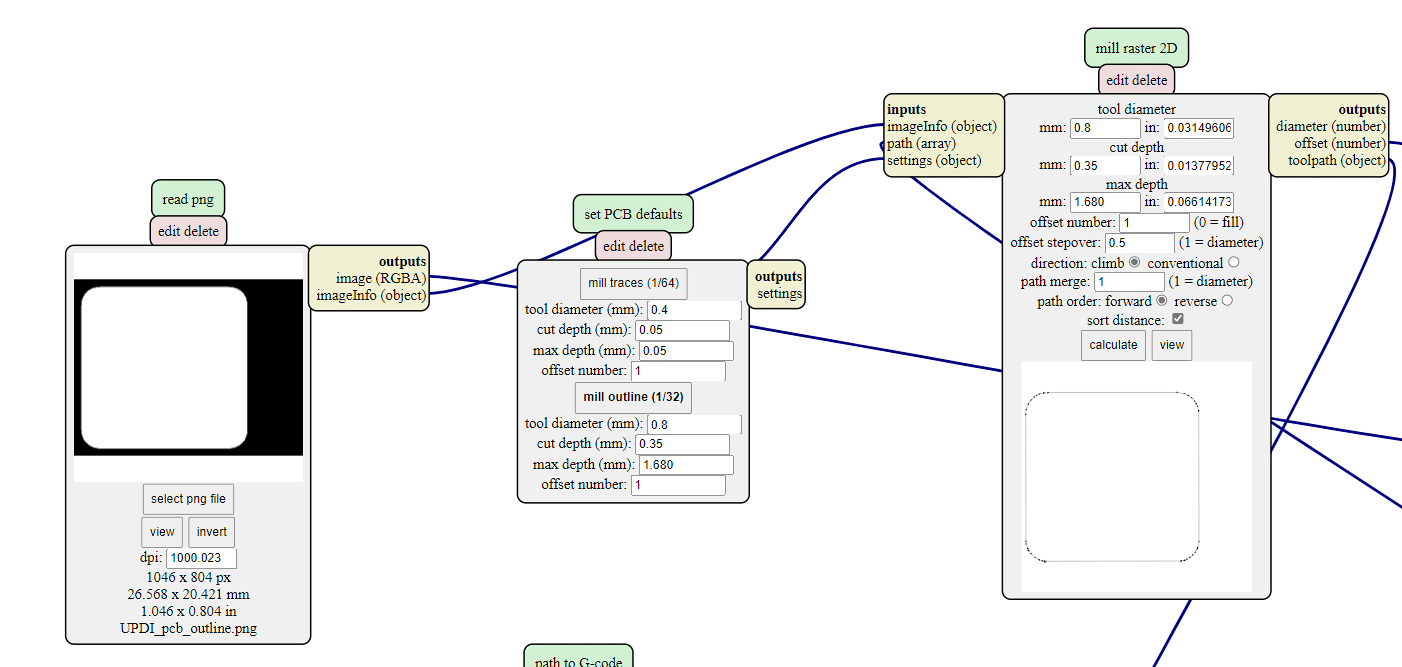

Skeatz Mods

Skeatz Mods was created by Mr Steven Chew to facilitate

the generation of 2D CNC Milling

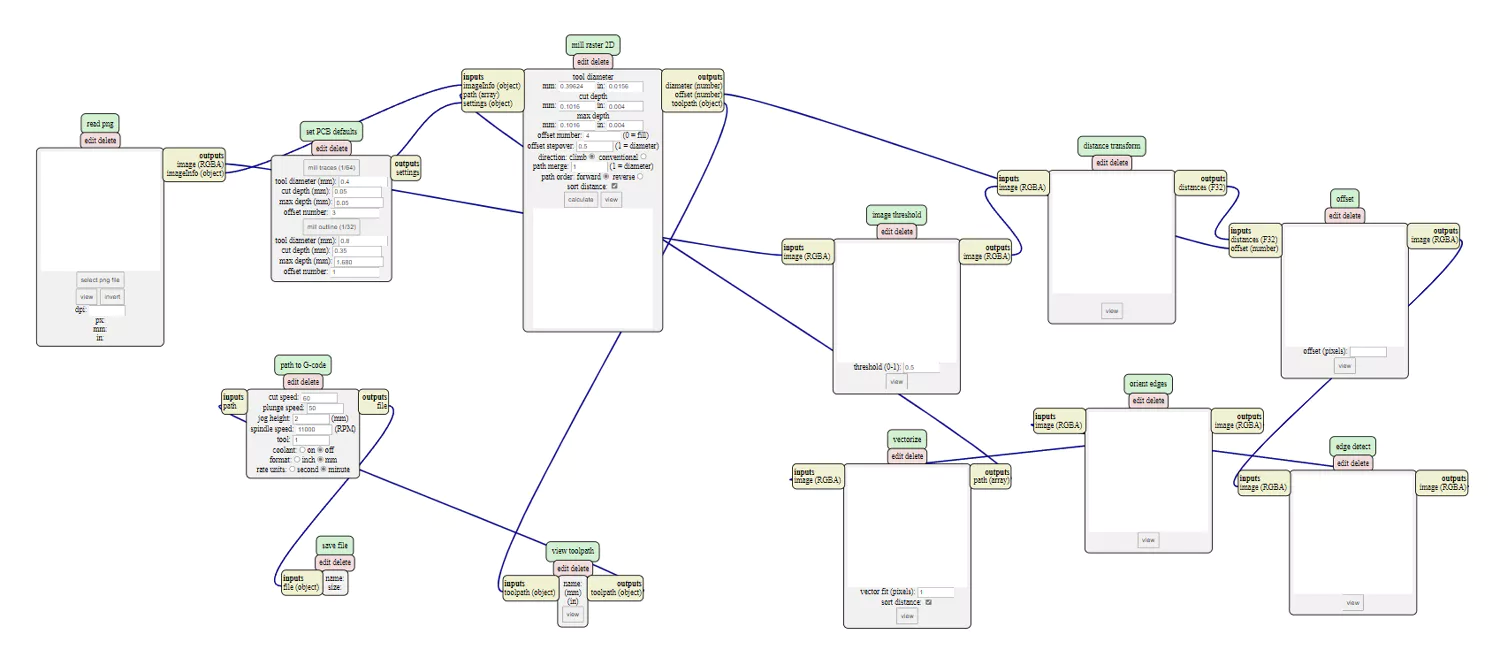

Overview

All the various settings and toggles to fine-tune the

g-code

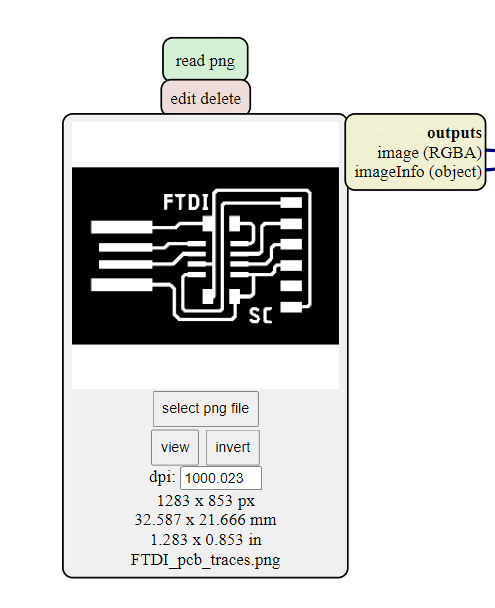

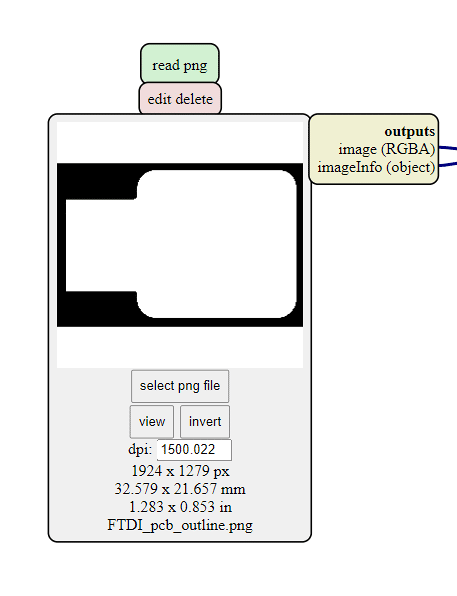

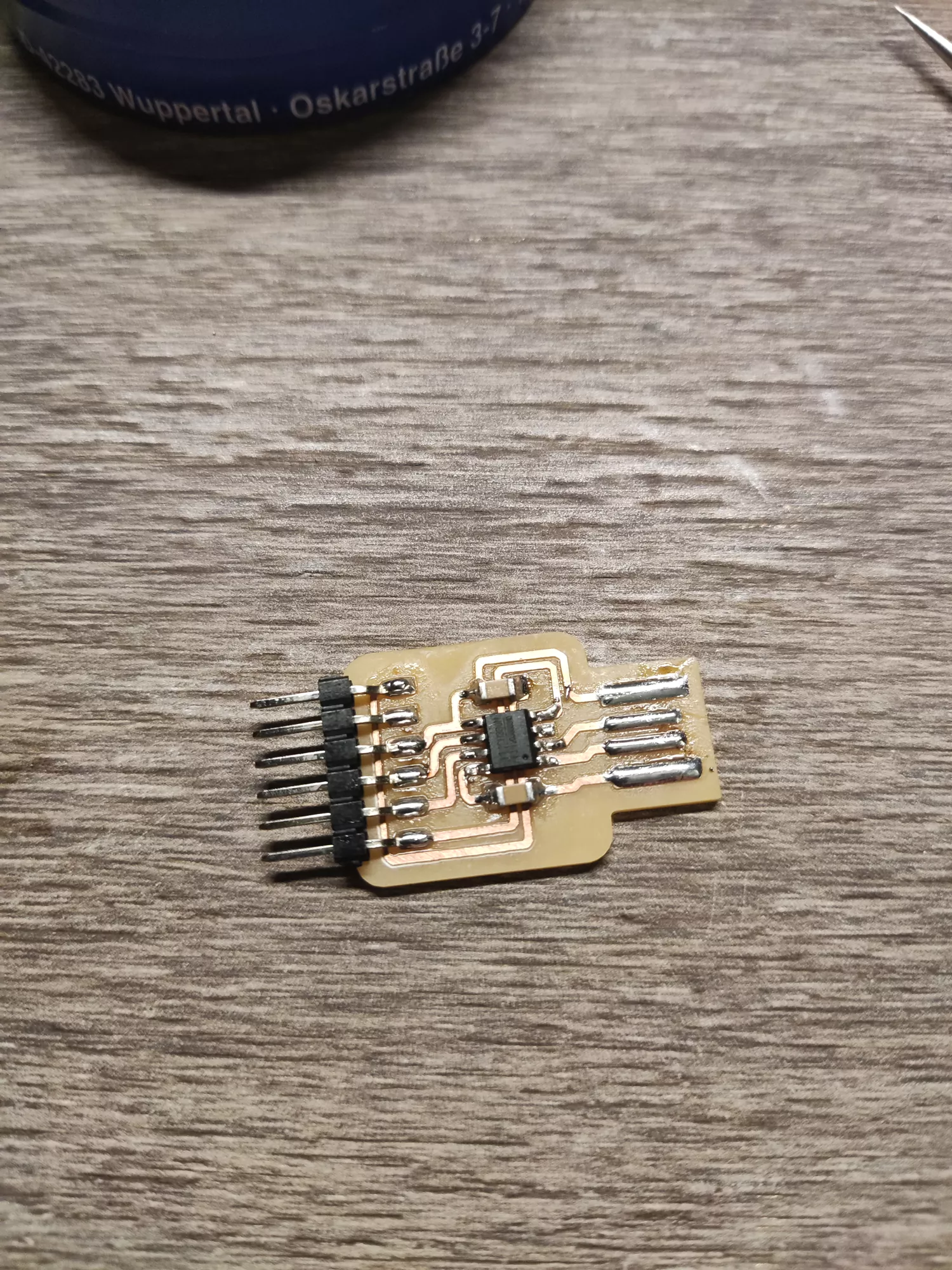

FTDI Traces

My FTDI PCB board design provided by Mr Steven Chew

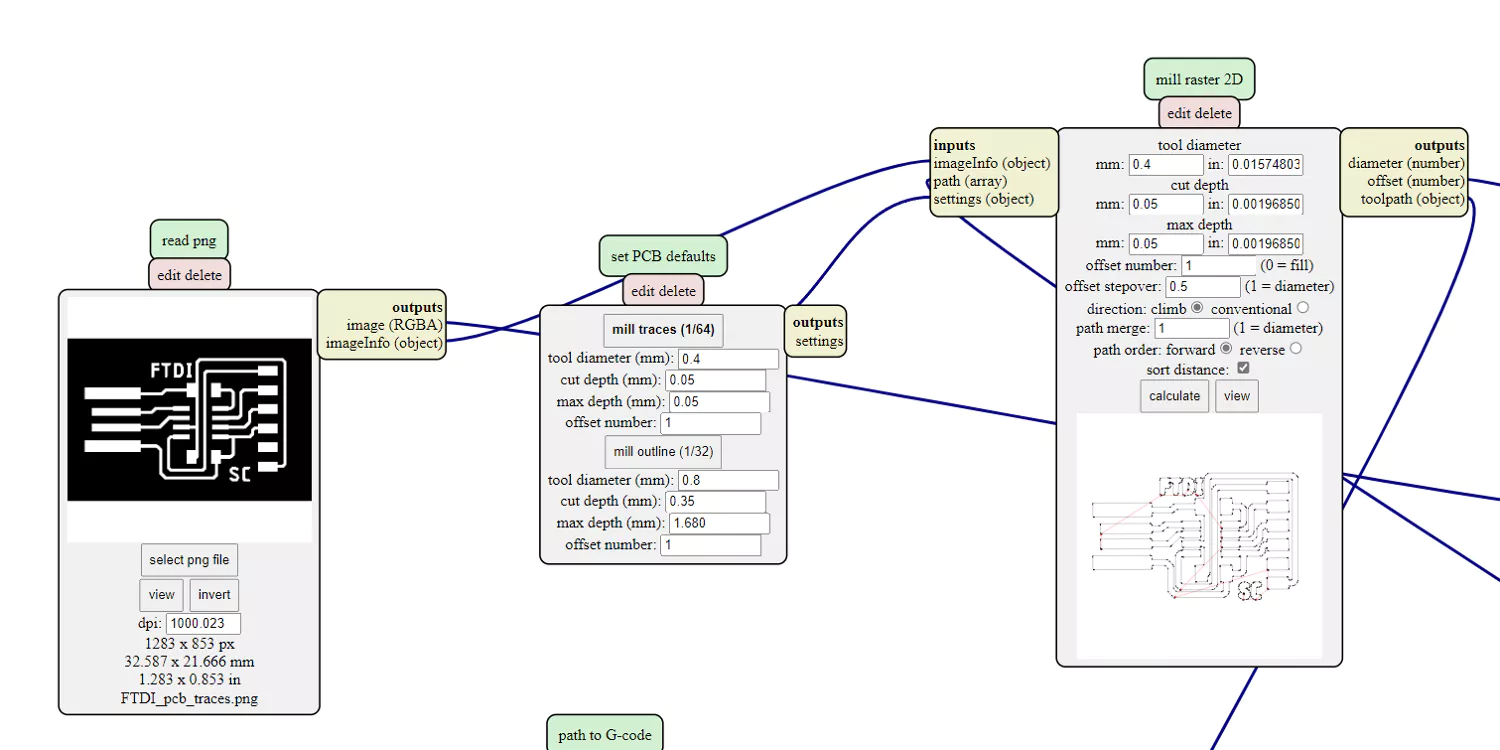

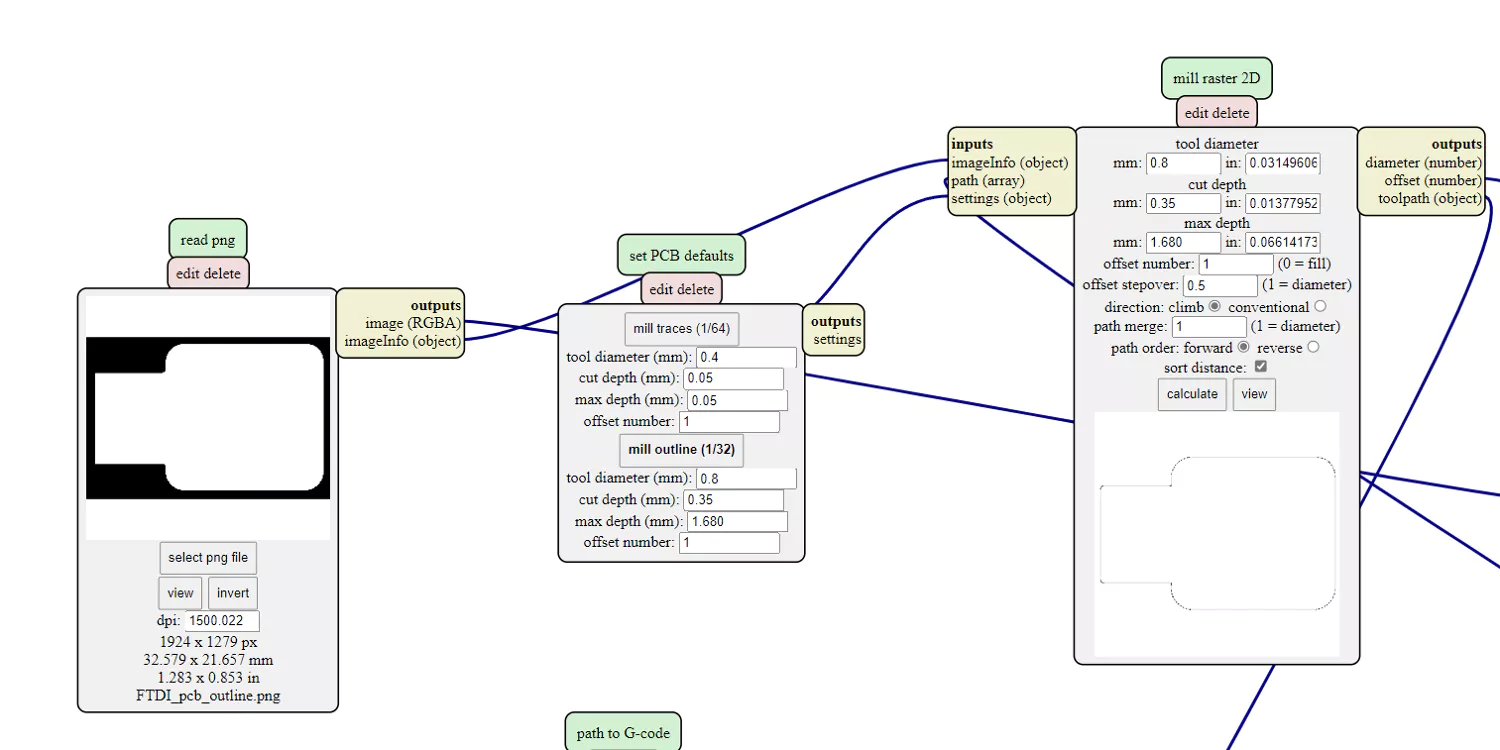

FTDI Settings

FDTI G-code settings

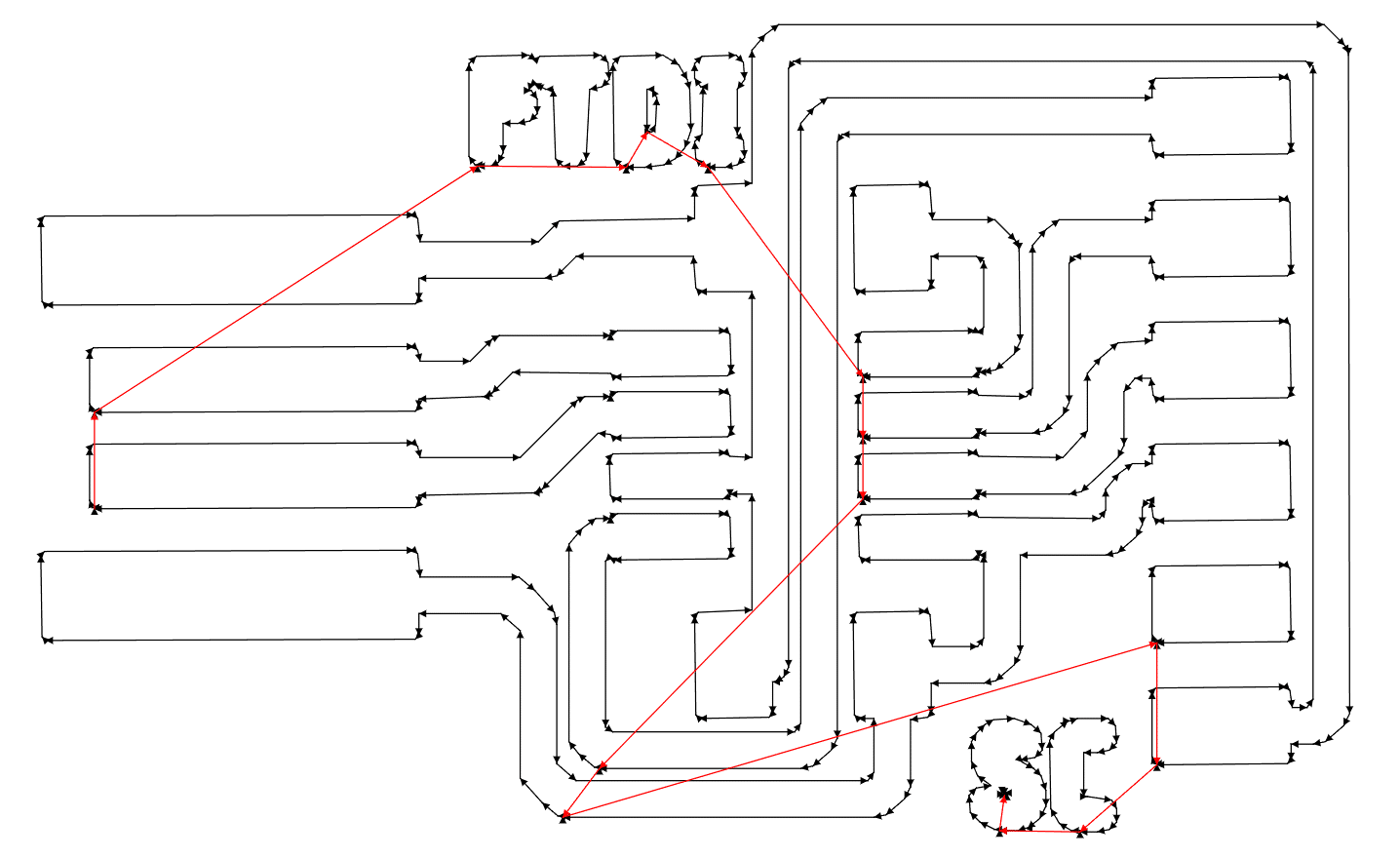

FDTI Toolpath

The FDTI toolpath generated

FDTI Outline

To remove the FDTI board from the copper

FDTI Outline Settings

FDTI outline G-code settings

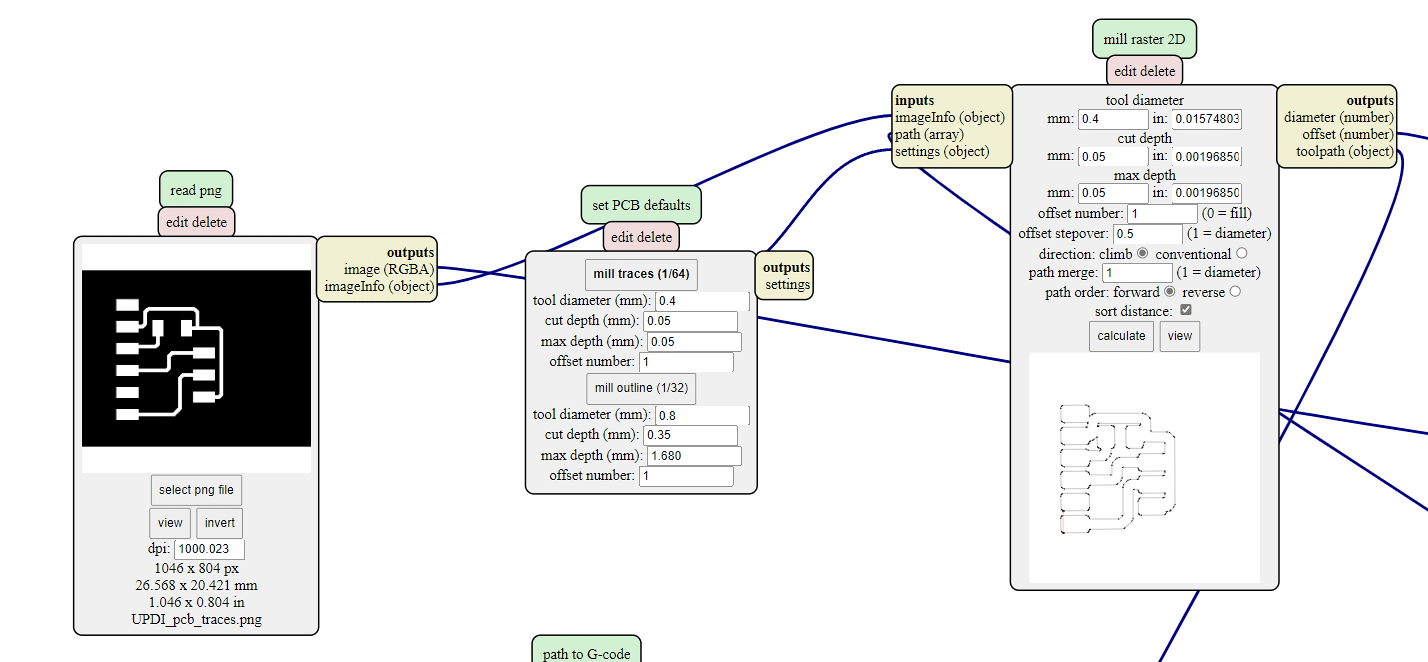

UPDI Settings

UPDI G-code settings

UPDI Outline Settings

UPDI Outline G-code settings

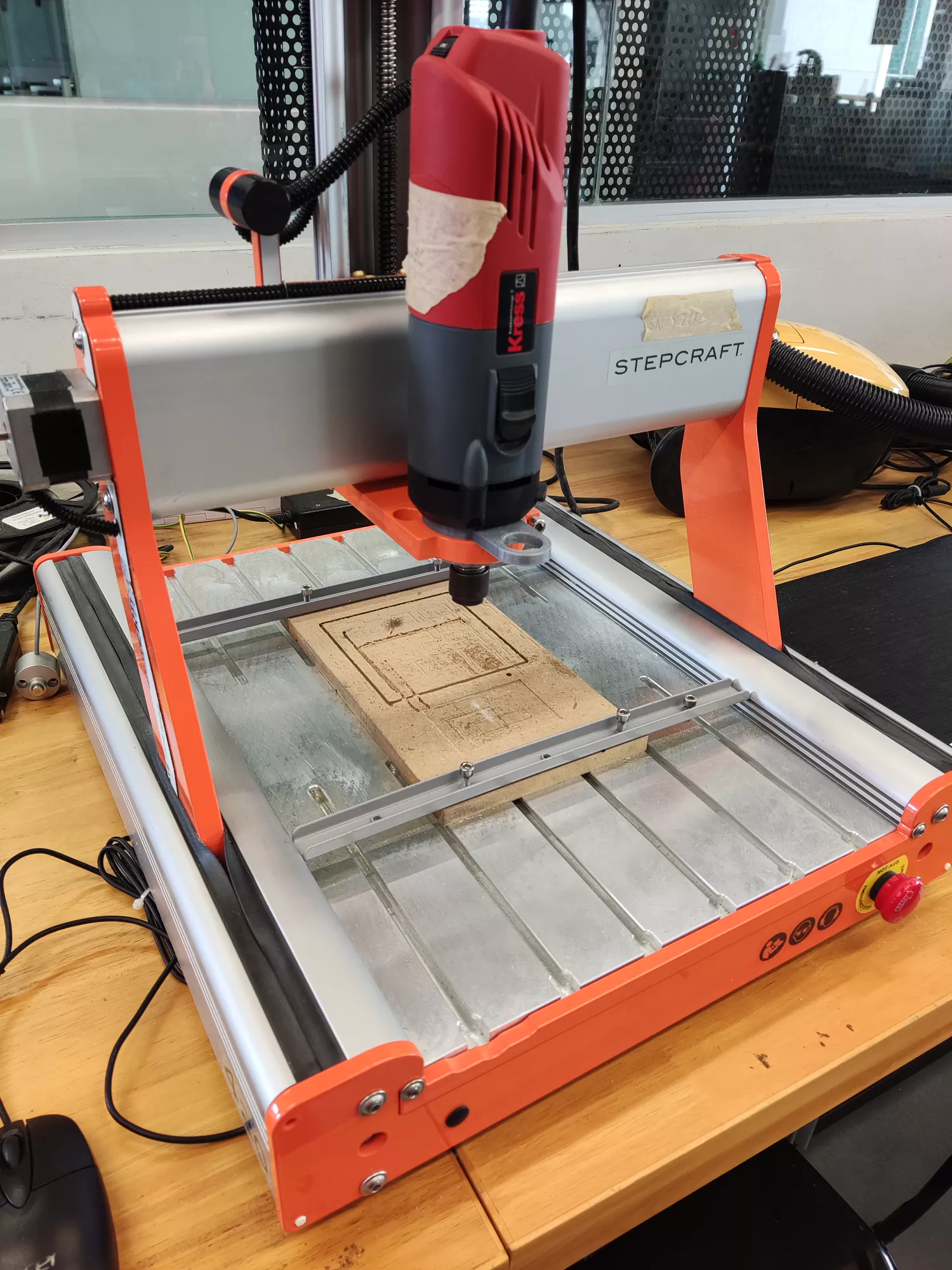

Stepcraft 420

The desktop CNC machine used for PCB milling

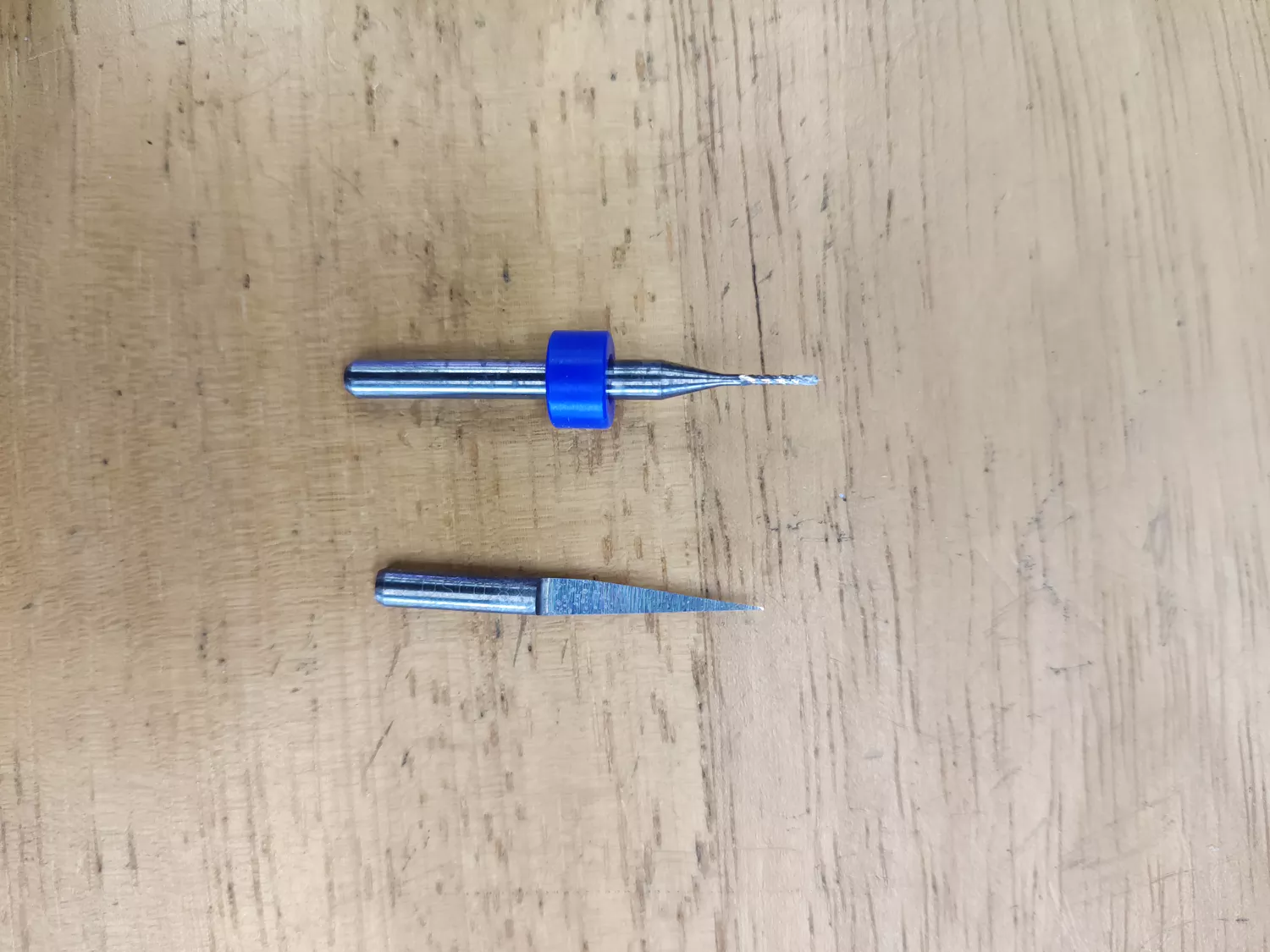

Drill bits

0.8mm flat endmill & 0.1mm 10deg engraving bit

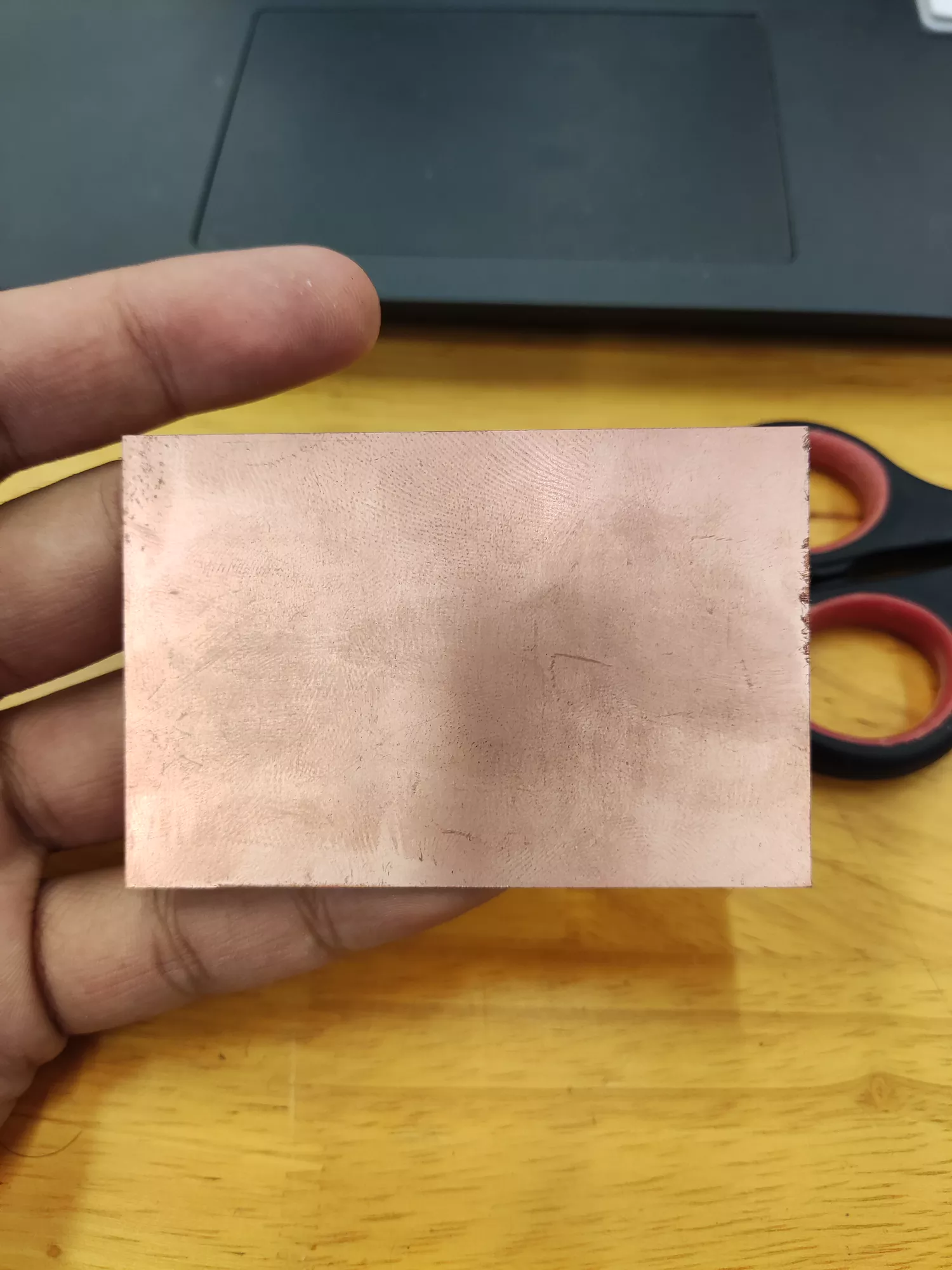

Copper Board

A thin layer of conductive copper

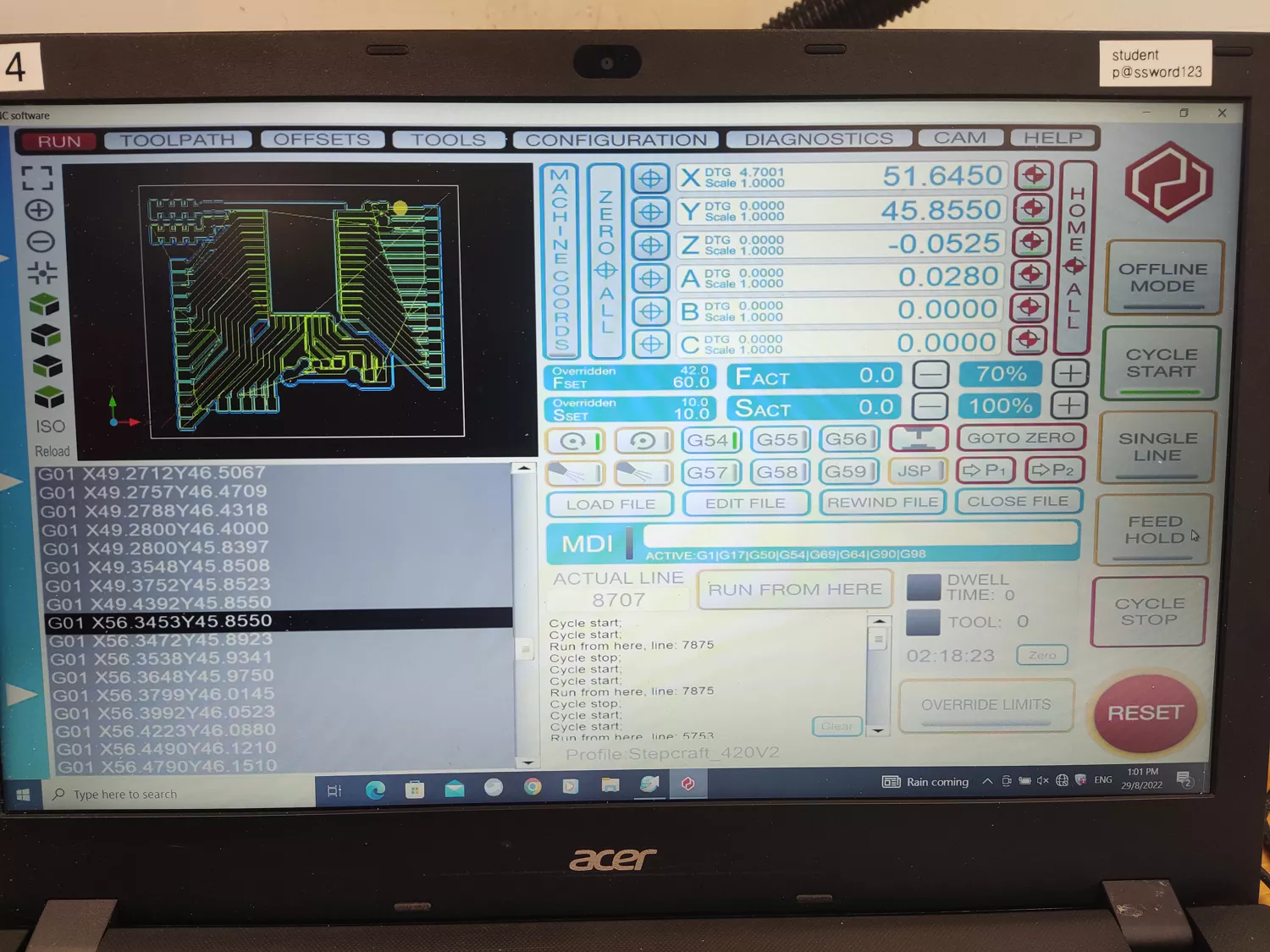

CNC Software

The controller for the Stepcraft 420 CNC

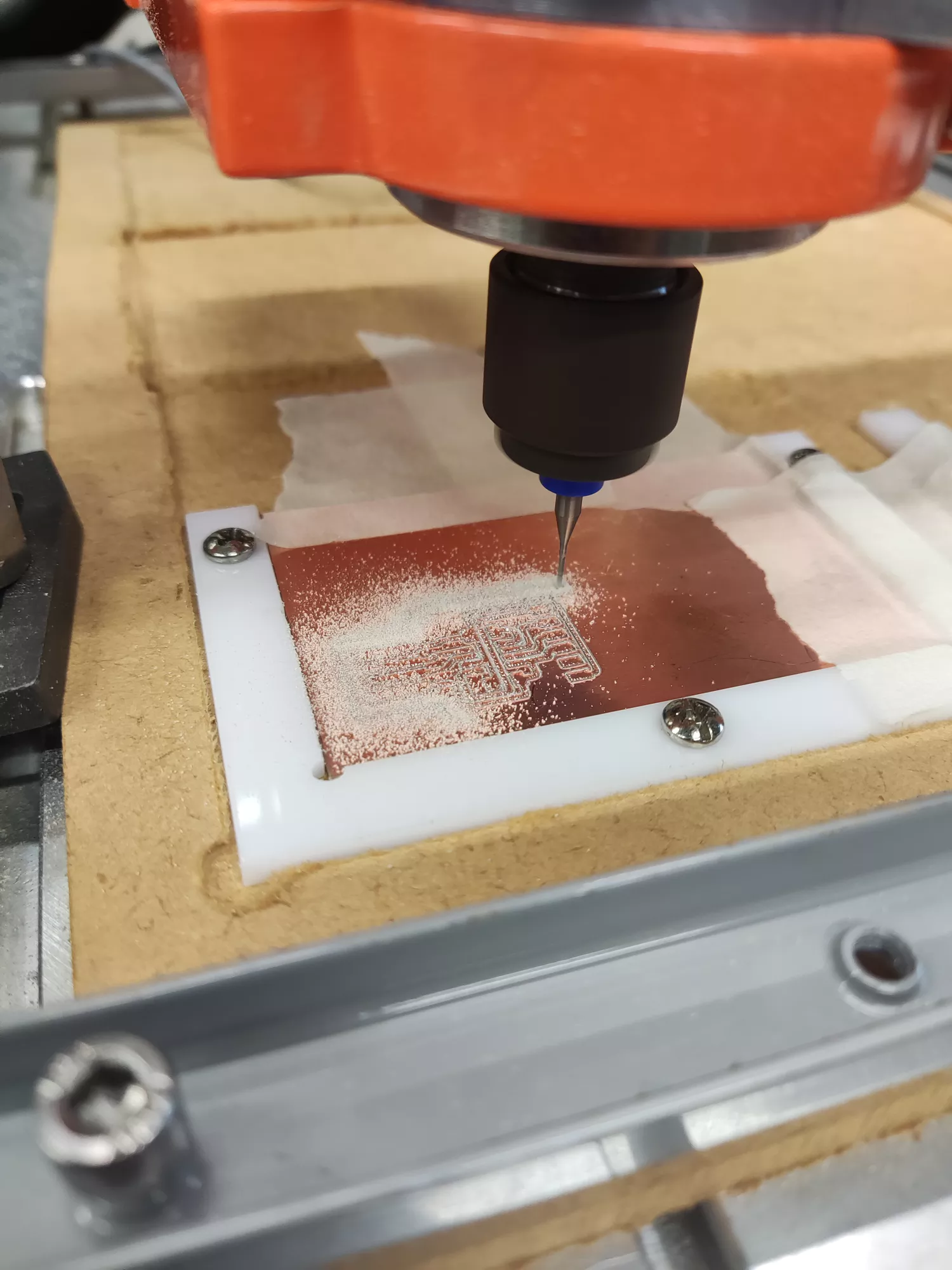

Milling of FDTI PCB

.

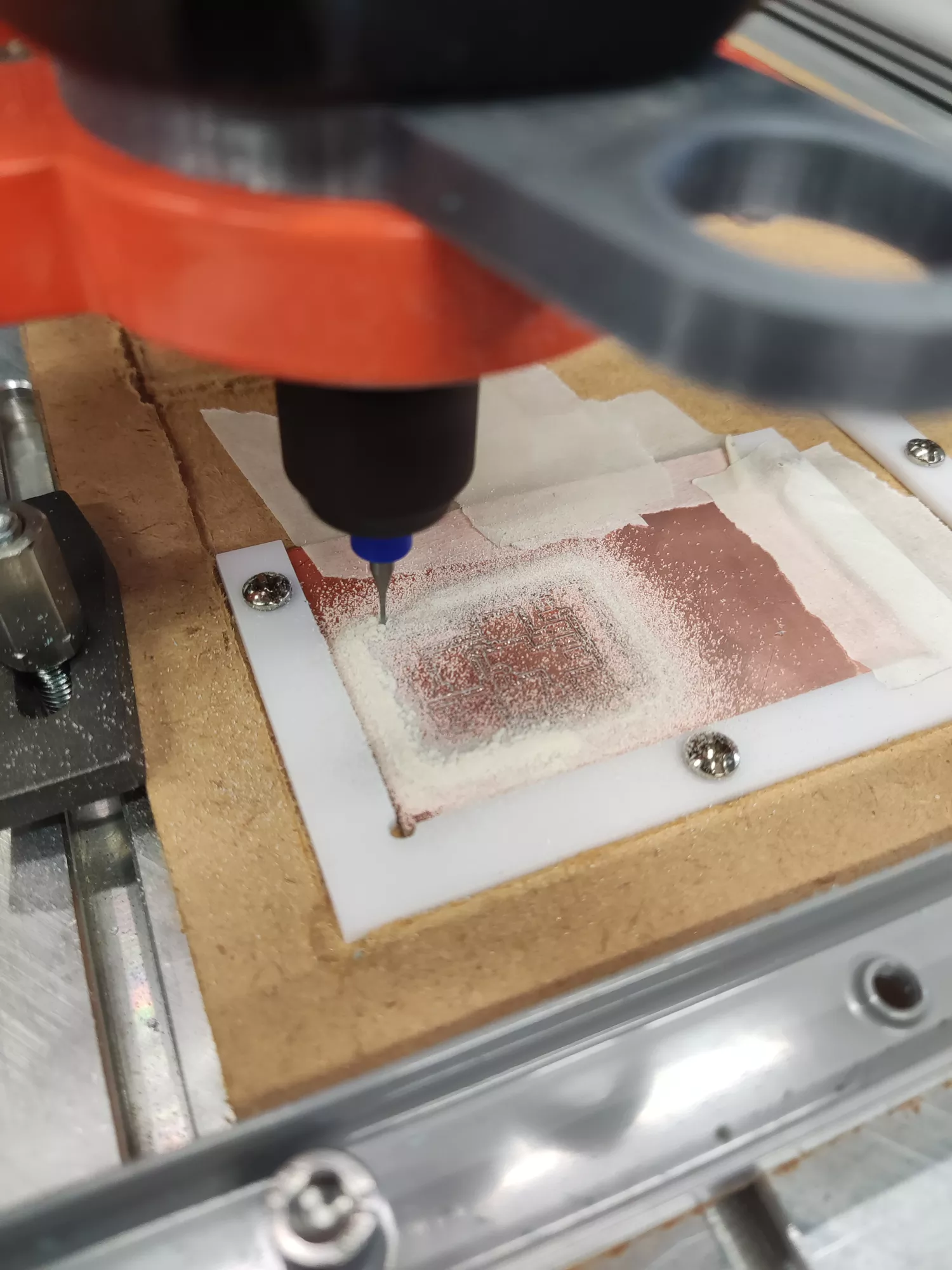

Milling of UPDI PCB

.

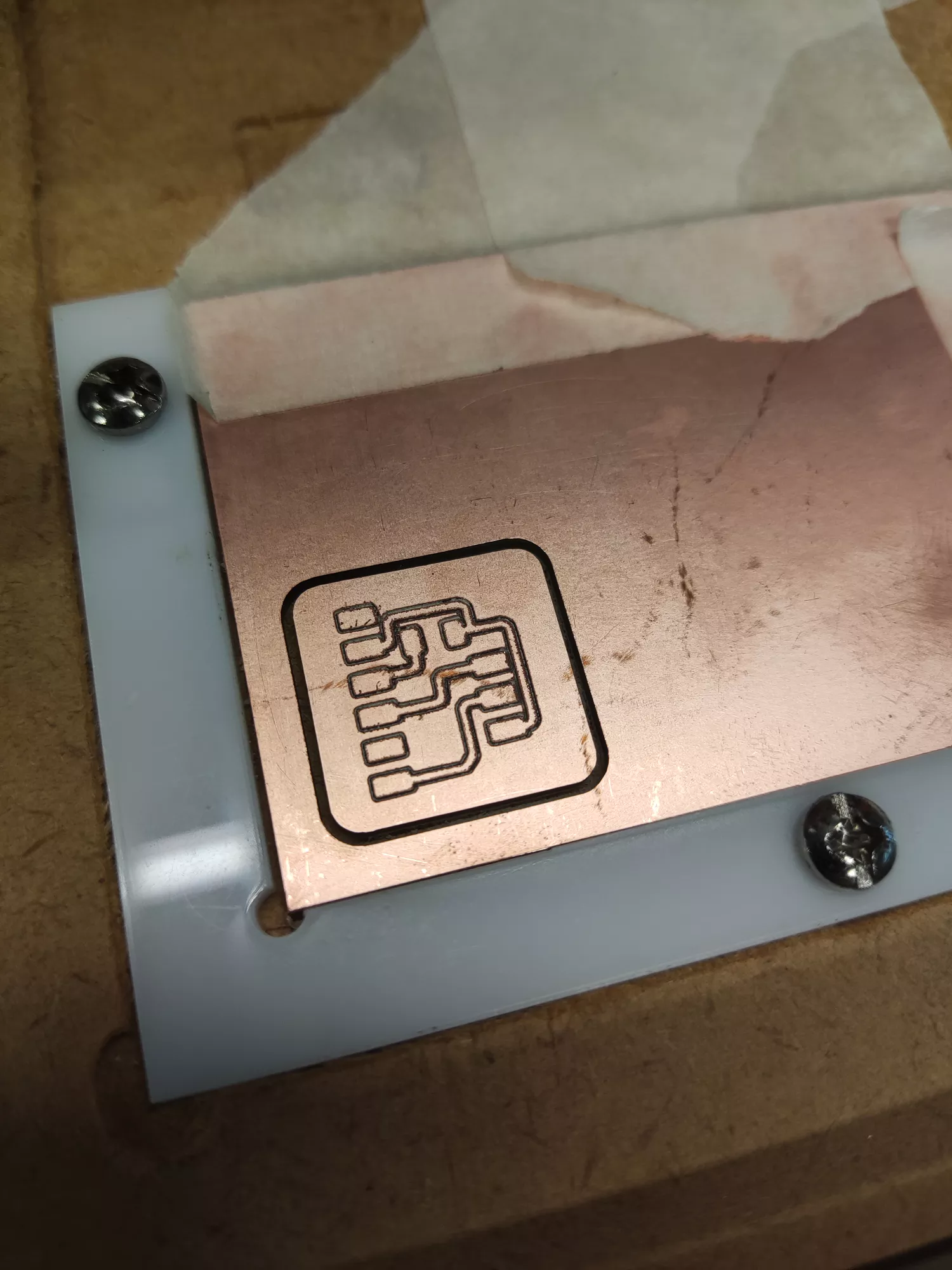

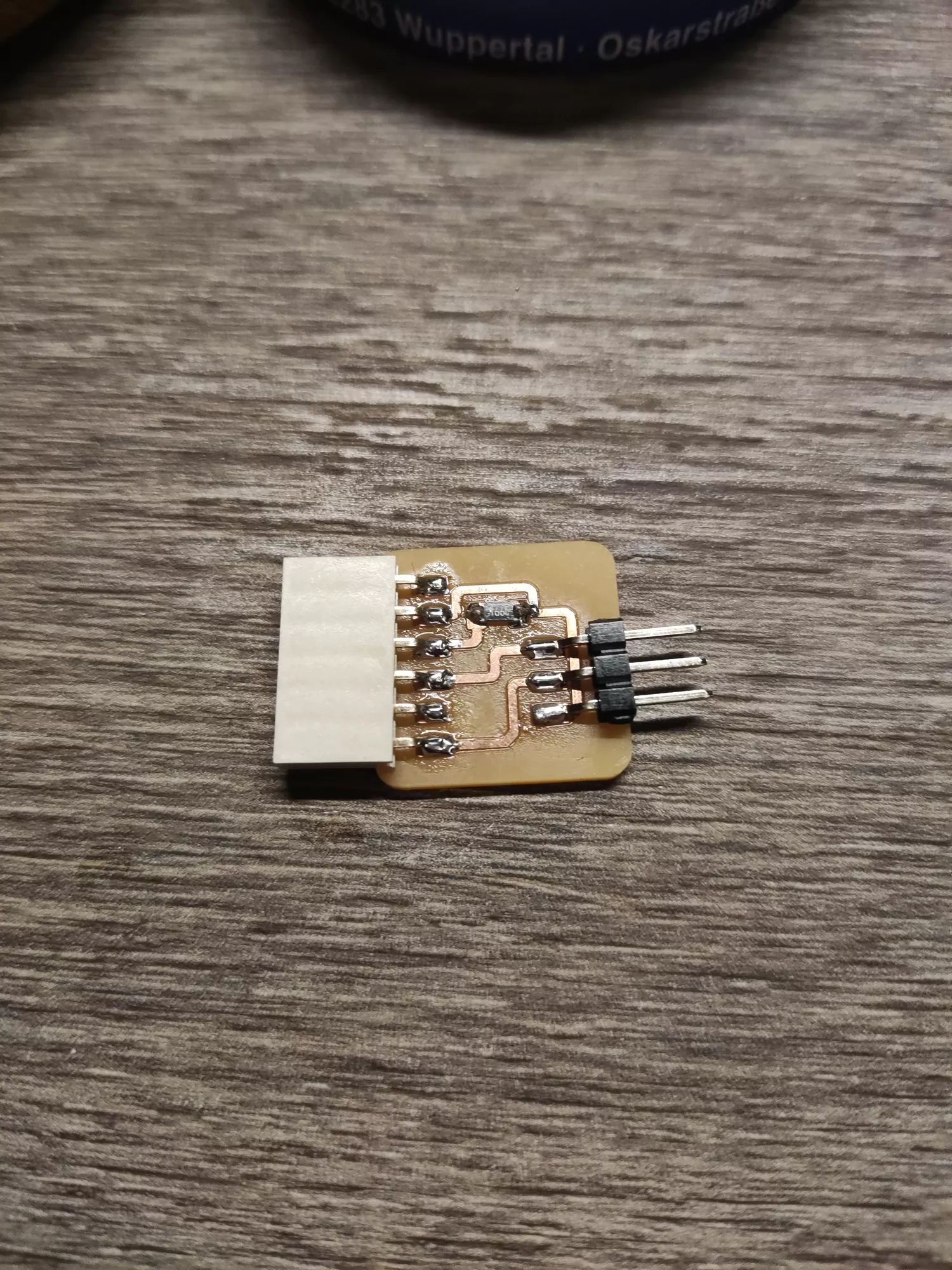

Completed UPDI PCB

crisp, sharp edges along the traces

Soldering Preperation

Soldering Iron, flux and various components

Soldered, Assembled FDTI Board

.

Soldered, Assembled UPDI Board

.

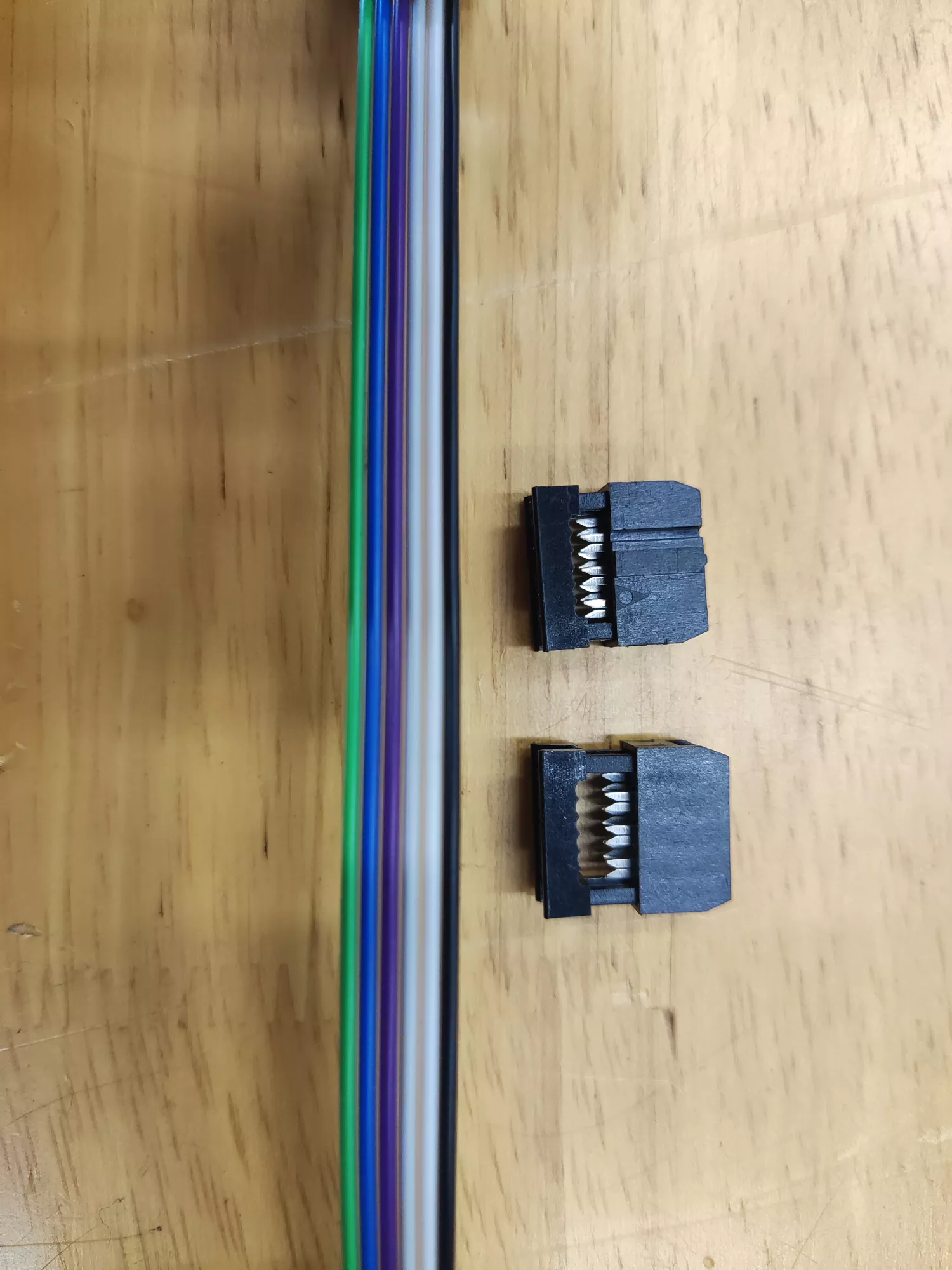

Programming Cable

A ribbon cable and two insulation displacing connectors

(IDC) connectors are needed.

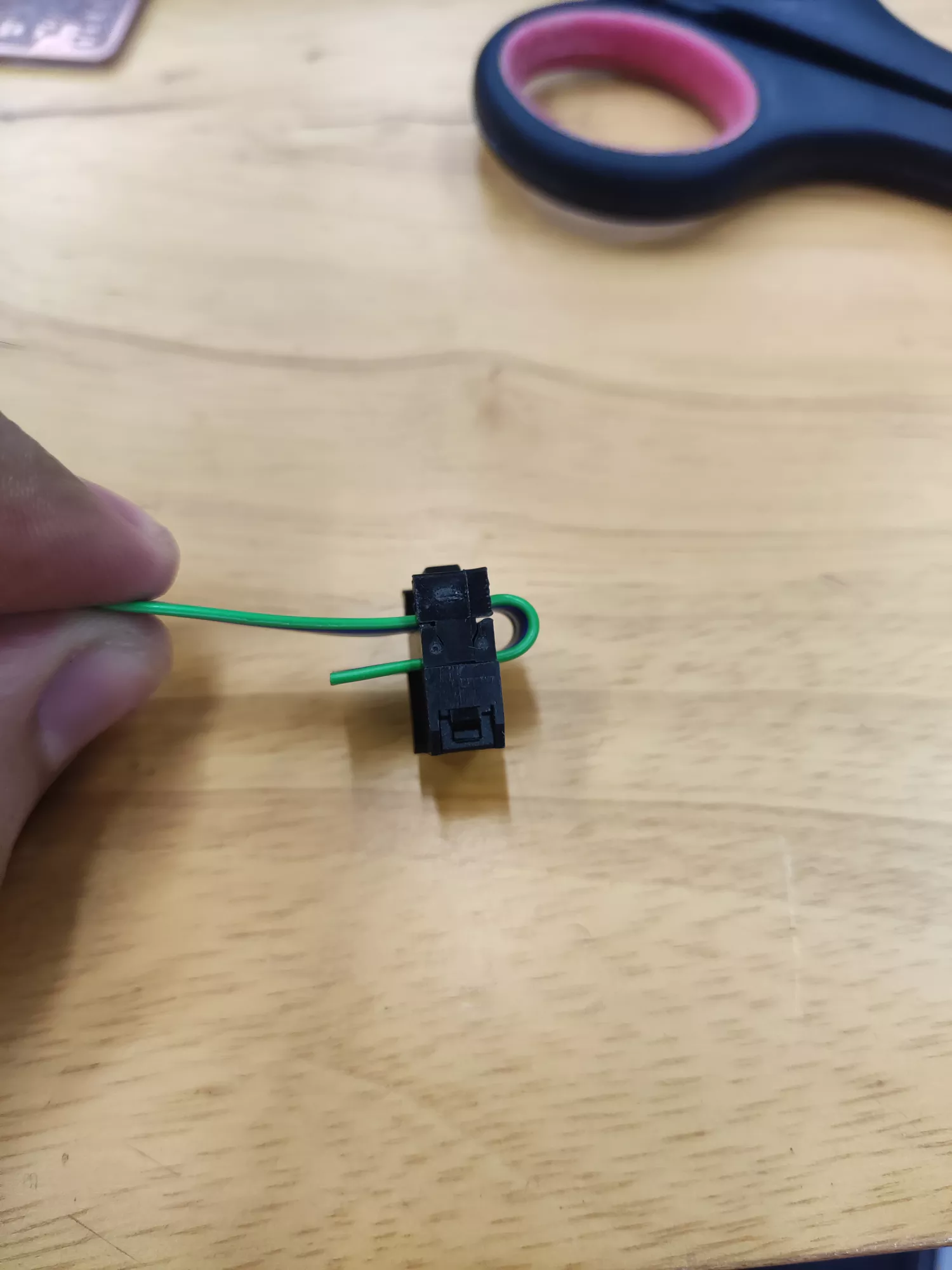

Crimping

The ribbon cable is inserted into the IDC connector.

Completed Cable

The connectors are attached at both ends.